Fermentis SafCider™ AS-2 Active Dry Cider Yeast

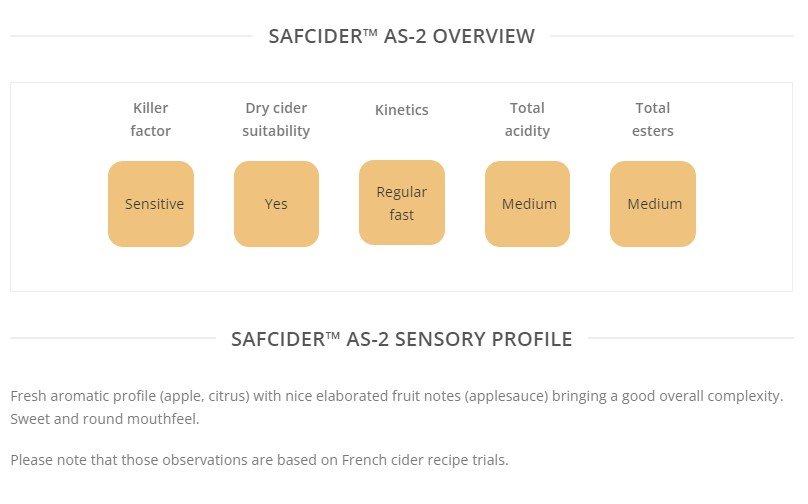

The best cider yeast for a fresh aromatic profile (apple, citrus) with nice, elaborated fruit notes (applesauce) bringing a good overall complexity.

DOSAGE

– 10 to 20 g/hl for first fermentation

USAGE

For sweet and dry ciders, even under difficult fermentation conditions. Sweet and round mouthfeel.

REHYDRATION PROCEDURE

Direct inoculation:

– Pour the yeast on the surface of at least 10 times their weight of must (possibly directly on the top of the tank or during tank filling after clarification).

– Gently stir to avoid or break clumps.

– Immediately transfer into the tank via a pumping over with aeration (or homogenize tank volume).

With prior rehydration:

– Pour the yeast on the surface of 10 times their weight of tap water at room temperature.

– Gently stir to avoid or break clumps.

– Wait for 20 minutes and transfer into the tank via a pumping over with aeration.

TECHNICAL CHARACTERISTICS

– Very good settlement strength even with its sensitive to killer phenotype

– Regular to fast kinetic

– Broad fermentation temperature spectrum: 10-30°C (50-86°F)

– Low nitrogen requirements: Ratio YAN**(mg/L)/Sugar(g/L) > 0.7 – 0.8

– Good assimilation of fructose

– Maximum initial SO2 level recommended: 100mg/L and low production of acetaldehyde and SO2

– Medium malic acid consumption (up to 0.9g/L)

– Medium 2-phenylethanol and ester producer. Good balance between acetate (amylic) and ethyl (fruity) esters

The best cider yeast for a fresh aromatic profile (apple, citrus) with nice, elaborated fruit notes (applesauce) bringing a good overall complexity.

DOSAGE

– 10 to 20 g/hl for first fermentation

USAGE

For sweet and dry ciders, even under difficult fermentation conditions. Sweet and round mouthfeel.

REHYDRATION PROCEDURE

Direct inoculation:

– Pour the yeast on the surface of at least 10 times their weight of must (possibly directly on the top of the tank or during tank filling after clarification).

– Gently stir to avoid or break clumps.

– Immediately transfer into the tank via a pumping over with aeration (or homogenize tank volume).

With prior rehydration:

– Pour the yeast on the surface of 10 times their weight of tap water at room temperature.

– Gently stir to avoid or break clumps.

– Wait for 20 minutes and transfer into the tank via a pumping over with aeration.

TECHNICAL CHARACTERISTICS

– Very good settlement strength even with its sensitive to killer phenotype

– Regular to fast kinetic

– Broad fermentation temperature spectrum: 10-30°C (50-86°F)

– Low nitrogen requirements: Ratio YAN**(mg/L)/Sugar(g/L) > 0.7 – 0.8

– Good assimilation of fructose

– Maximum initial SO2 level recommended: 100mg/L and low production of acetaldehyde and SO2

– Medium malic acid consumption (up to 0.9g/L)

– Medium 2-phenylethanol and ester producer. Good balance between acetate (amylic) and ethyl (fruity) esters

The best cider yeast for a fresh aromatic profile (apple, citrus) with nice, elaborated fruit notes (applesauce) bringing a good overall complexity.

DOSAGE

– 10 to 20 g/hl for first fermentation

USAGE

For sweet and dry ciders, even under difficult fermentation conditions. Sweet and round mouthfeel.

REHYDRATION PROCEDURE

Direct inoculation:

– Pour the yeast on the surface of at least 10 times their weight of must (possibly directly on the top of the tank or during tank filling after clarification).

– Gently stir to avoid or break clumps.

– Immediately transfer into the tank via a pumping over with aeration (or homogenize tank volume).

With prior rehydration:

– Pour the yeast on the surface of 10 times their weight of tap water at room temperature.

– Gently stir to avoid or break clumps.

– Wait for 20 minutes and transfer into the tank via a pumping over with aeration.

TECHNICAL CHARACTERISTICS

– Very good settlement strength even with its sensitive to killer phenotype

– Regular to fast kinetic

– Broad fermentation temperature spectrum: 10-30°C (50-86°F)

– Low nitrogen requirements: Ratio YAN**(mg/L)/Sugar(g/L) > 0.7 – 0.8

– Good assimilation of fructose

– Maximum initial SO2 level recommended: 100mg/L and low production of acetaldehyde and SO2

– Medium malic acid consumption (up to 0.9g/L)

– Medium 2-phenylethanol and ester producer. Good balance between acetate (amylic) and ethyl (fruity) esters